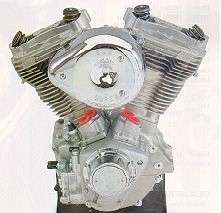

| Performance and

Technical information on Stage 3 modifications to a Harley-Davidson 1340 Evolution

motorcycle engine. Build

low cost, maximum performance street engine

or

How to get 95HP from your 1340 Evolution engine.

|

You have decided that your current

engine isn't getting the job done. You have made Stage 2 changes to your bike and are still looking for more

power. You are ready for a series Stage 3 engine. These modifications are a little more

complicated than the bolt-on Stage 3 engine.

Better flowing heads and increased compression ratios are the usual way to

make 90+ horsepower. Motorcycle Performance Guide is about

to blow the lid off this idea. We achieved 95.4 horsepower at the

rear wheels using un-ported Harley-Davidson 1340 heads and

increasing the compression with domed pistons. Contrary to what many

performance shops try to tell you, we were able to break the 90 horsepower

mark without larger valves, porting and polishing the Evolution

heads.

There are many companies out there that are

competing for the dollars that Harley-Davidson owners are willing to spend on

their bikes. As an owner, you will be bombarded with a vast array of promises, claims and

inaccuracies in an effort to separate you from your money. Reading between the lines on

many of the performance claims can be bewildering.

Does the Harley-Davidson world need

another engine modification article? We decided it does, since the results

obtained by the engine upgrades listed here provided significantly better results than

those documented by the popular magazines aimed at the V-Twin crowd. The Motorcycle

Performance Guide staff continues to obtain better results than the "experts" in

the press and most performance shops.

How to build your own Stage Three engine

|

This Stage Three engine requires internal changes to the engine.

Disassembly of the top end of the engine is required. Some special tools

and training is required to perform these upgrades. Unless you are a very good

mechanic and have access to a machine shop, it is recommended you find a competent shop to

perform these modifications. For those of

you that want to assemble the engine yourself, Motorcycle Performance Guide recommends you

obtain the proper service manual for your bike.

Over the past several years we have installed and

tested many manufacturers components. The list of parts used in building

this engine is the end result of this testing. The best and least

expensive of the components were selected and tested as a single package.

The horsepower your bike produces may vary from the results produced here.

If you use different parts or do not properly tune your engine, power may

change significantly. Motorcycle Performance Guide assures you that the

parts list and results are presented as accurately as possible.

All the parts used

in this engine are

readily available through local shops, after-market parts companies

and your Harley-Davidson Dealer. The components were

installed and tested on a 1994 FXD Dyna Low Rider. Dyno tuning is required to

achieve the results listed. All components were installed according to the manufacturer

instructions supplied.

| Building your Stage 3 engine

Disconnect battery

Drain gasoline from tank

Remove gas tank

Disassemble the engine top end

Remove heads, cylinders and pistons

Remove cam, lifters and lifter blocks

Remove old cam bearing

Remove stock clutch

Send heads to machine shop to install parts and do valve job

Send cylinders to machine shop to fit new pistons

Install cylinders with new pistons

Install upgraded cylinder heads

Install new cam bearing

Install new cam

Install ignition module

Install lifter blocks with new lifters

Install adjustable pushrods

Install intake manifold and carburetor

Install new clutch

Install exhaust system

Remove exhaust system baffles

Change engine oil and filter

Change transmission oil

Add primary chaincase oil

Install new spark plugs

Set static ignition timing

Road test the bike

Dyno Tune the bike

Enjoy the ride |

The results of the Dyno testing were excellent. The test results showed the engine

producing 95.4 horsepower @ 5600 RPM and 95.3 ft. lbs. of torque @ 4600 RPM.

While the power curve on this engine

was optimized for drag racing and dyno shootouts, it still manages to

produce over 80 ft.lbs.. of torque from 3900 to 6000 RPMs. That is some

serious power to the rear wheels.

This engine is producing

40 horsepower more than a stock bike. Not bad for the relatively low investment in time and money required to get these results.

Just how fast is fast enough is a matter

of opinion. This 94 FXDL was taken to the drag strip in order to establish what 1/4 mile times could be

done. The bike proved to be a very potent H-D drag race bike by turning times in the

11.80 range with 114 MPH speeds. The bike will accelerate to 90+ MPH in 1/8

of a mile.

The results are due to a well matched set of parts

being installed in the engine. This is an engine combination that many

Harley shops do not want you to know about. Who would believe stock

Evolution heads could make over 90 horsepower.

Just because the heads were not ported and

polished, don't think that you can achieve the high horsepower numbers

without making some changes to the heads. The Manley performance valves

and the 5 angle valve job provide big improvements in air flow through the

ports. This is an important part of making good horsepower. Don't forget

to have the spring clearance set for .600" lift cams. The SE-57 has a

.575" bump on it. The JE 10.5:1 pistons are machined to accept a high

lift cam.

The performance of the Screamin Eagle SE-57

camshaft was impressive, producing strong torque to match the horsepower

potential. Past experience indicated that cams with 252 degrees of

duration make excellent street cams. This Harley-Davidson camshaft did not

disappoint.

The SuperTrapp 2-1 exhaust system with the

internal baffles removed was an important component in creating this high

horsepower. Installation of the baffles and use of 18 disks results in a

5-7 horsepower drop, but the torque remains the same. The horsepower curve

peaks drops to 5700 RPM and the torque peak drops to 3900 RPM. This change

in power curve makes the engine very potent on the street.

If don't have the money to purchase all the

parts listed for this engine, we recommend you make the following changes

| Use your re-jetted CV carburetor in

place of the Mikuni HSR-42. The CV is capable of supporting a 90 HP

engine. Just keep your Screamin Eagle air filter clean and make sure

the carburetor is well tune. |

| The Cycle Shack Slash-cut exhaust system

or Slip-on mufflers on stock header pipes are a low cost alternative

to the SuperTrapp 2-1. While the maximum power of the 2-2 exhaust

system is not going to match the 2-1 system, expect only a small

horsepower drop. |

| The Barnett Extra Plate clutch is a good

alternative to the Rivera Pro Clutch. With the extra power available

from the engine, the stock clutch will not last very long if your

riding style is aggressive. While the Barnett upgrade will not last

like the Rivera, the cost difference is significant. |

The ability to create similar results with

other manufacturers parts is a distinct possibility. Motorcycle Performance Guide

choose to

work with parts that had proven ability to provide increased horsepower and torque. If you

use the parts listed in the "Ultimate Street Engine" series of articles, there

is little doubt in our minds that your can duplicate our results, provided the engine is

in good mechanical shape and properly tuned. Optional parts that have similar

specifications to the components used in our engine should provide very similar results. A

matched set of engine components, careful assembly and dyno tuning are the keys to

building a killer street engine. May your results be a successful as those we have

documented. |