Remove old cam bearing. Use a small,

inside bearing or bushing puller to remove the cam bearing. Replace the old cam bearing

with a new Torrington B-138. Do not use a late model H-D OEM

bearing with any performance camshaft.

Tricks of the trade:

The old camshaft can be used as alignment tool and press for

installation of the new bearing. Place the breather gear in place. The breather gear and

pinion gear effectively form an alignment tool so the cam bearing on the old camshaft can

be put in place with very little force required.

A few light taps on the end of the camshaft with a polyurethane or

rubber mallet may be required to make sure the cam bearing is pressed completely into the

engine case. |

Place the new cam bearing on the installation tool or on the end of

the old camshaft and install the new bearing. When installing the

Torrington bearing, remember to install it with the printed edge facing

outward.Make sure the cam bearing is pressed

completely into the engine case.

Aftermarket camshafts require a cam shim washer be placed over the

rear of the camshaft prior to installation. Using a set of dial calipers, measure length

of old cam from the front of the timing gear to the forward most area of cam bearing area.

Measure the same length of the new cam. The difference should be between .050 and .060

inches. A shim of the proper length is required. If no caliper is available to measure the

cams, install a .055 cam shim at rear of new camshaft. This is generally the correct shim

to install.

Place the proper cam shim over the rear bearing surface of the new

camshaft.

Place the thrust washer at the rear of the new camshaft.

Place a coating of assembly lubricant on the camshaft lobes,

bearing, bushing areas and camshaft gear. This will protect the camshaft and lifters

during engine startup. If assembly lube is not available, synthetic motor oil is a

suitable alternative.

Figure 8

Camshaft

Breather Gear

Pinion Gear |

Carefully place the new camshaft into the engine, making sure not to

damage the lobe or bearing surfaces. Make sure camshaft alignment mark matches with mark

on pinion gear.

Replace breather, making sure alignment marks on breather and cam

gear line up. Place nylon washer on end of breather

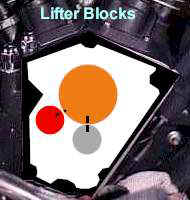

Install the lifter blocks using new gaskets or remove the lifter

holding tool, allowing the lifter to settle on the camshaft lobes.

Figure 10 |

The engine should look like Figure 10. The new camshaft is in place.

The lifters should be in place. It is a good time to check the work.

| Is the thrust washer in place? |

| Is the proper shim on the camshaft? |

| Is the pinion gear and cam gear aligned properly? |

| Is the breather gear and the cam gear aligned properly? |

| Is the nylon breather gear washer in place? |

If the answer is yes to all the questions, it is time to proceed.

Replace gearcase cover gasket.

| Replacement of camshaft bushing and camshaft oil seal in nose come

should be considered if the bike is over 5 years old or has over 50,000 miles on it. |

Liberally squirt engine oil over the camshaft, cam gear, pinion gear

and breather gear prior to closing up the engine. Place a few squirts of oil over the top

of each lifter. |